Direct Mount Free Stop Gravity Roller

With 2-Way Stop Device

Before you start: In addition to the size of the shade, you must establish the weight per M2≠= for the chosen fabric as this is key to determining which FreeStop spring to use.

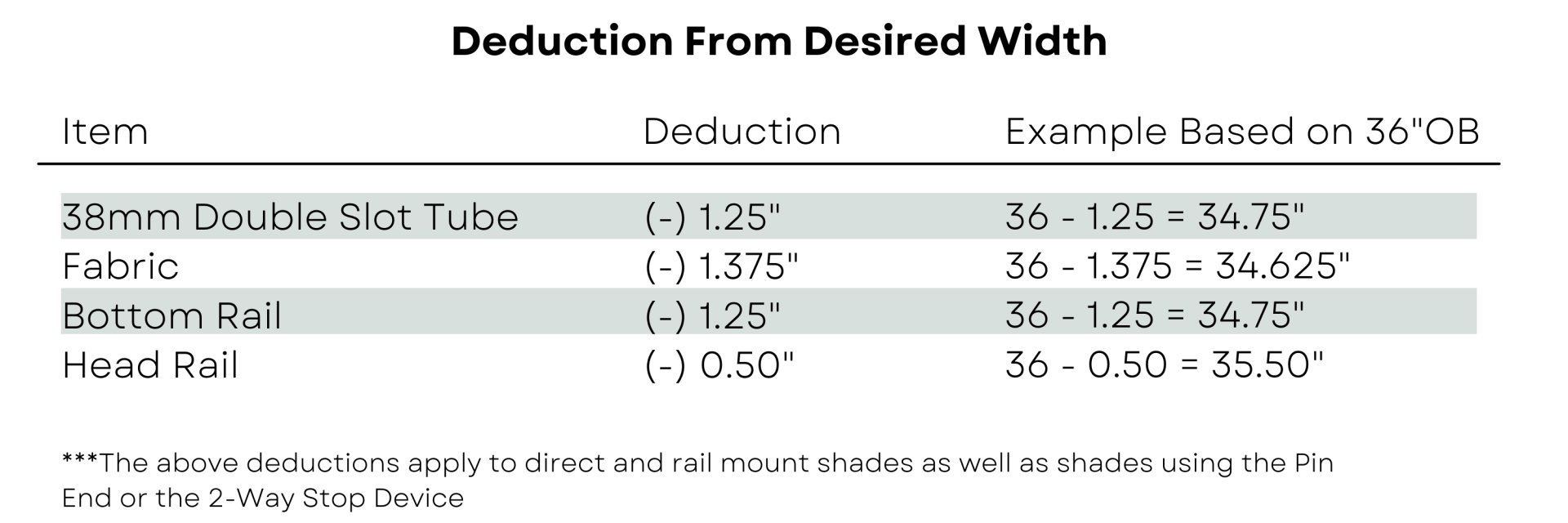

Step 1: Cut the aluminum and fabric for your specific shade. The recommended deductions are as follows:

Step 2: Attach the fabric to the tube and bottom rail per your preferred or established method.

Step 3: Using the Spring-Fabric info Chart, find the section that best reflects the weight of your fabric. It is recommended that you use the section closest to your fabrics weight. For example, when using a fabric with a m2 weight of 180g, use the section for 200g instead of the 150g. Each section will show which spring to use and how many pre-tension turns are required dependent on the shade width.

Step 4: Insert the spring into the tube from the left ensuring that the clutch head is seated fully into the tube. Ensure that the middle wheel on the 2-Way Stop is rotated all the way left before inserting it into the tube from the right or idle end side.

*NOTE: Wheel should be tensioned up against left stop.

Step 5: Using the Tension Tool or 3/8” closed end wrench, add the recommended tension/turns to the spring in a clockwise direction. The clutch head has an internal spring that must be depressed in order to apply the tension. Once the desired turns are applied, release the spring and the internal lock will hold the tension.

Step 6: Insert the Safety Tension Pin into the clutch head. This will ensure that the tension is not released inadvertently.

Step 7: Mount the shade onto your inspection station using properly spaced wheel adjust and pin end/stop device brackets. Note, brackets are to be spaced to the exact width of the requested shade width.

Step 8: Insert the squared tip of the clutch head into the matching opening in the wheel adjust bracket. Once the two parts are matched and the pin is partly inserted, remove the Safety Tension Pin. Keeping pressure to the left, use the built-in guide on the Pin End/Stop Device bracket to seat the squared tip of the 2-Way Stop Device.

Step 9: Operate the shade up and down repeatedly to ensure it is working properly. If the shade is moving in either direction of its own accord, use the adjustment wheel on the bracket to increase or decrease the tension on the spring. When spring is properly tensioned, the bottom rail will stay wherever placed.

Counter clockwise rotation will reduce tension.

Clockwise rotation will increase tension.

For Pin End

Step 10: Once the tension is set properly, lower the bottom rail to your desired max drop (we recommend 1” more than the ordered length, on a 36” drop we would pull the bottom rail to 37”). Putting pressure to the left of the shade, disengage the 2-Way Stop from the bracket and using your thumb and forefinger, turn the squared tip of the 2-Way Stop counter-clockwise until it will no longer turn and seat the 2-Way Stop back into the bracket. This will set the bottommost stop point for your shade. This does not need to be exact as it is intended to keep the fabric from being pulled off the tube inadvertently.

Step 11: Operate the shade and ensure that the bottommost setting is accurate. Once satisfied with the bottommost setting. Raise the bottom bar to the desired uppermost point. This is typically just below the fabric roll. Insert a 2.5mm allen wrench into the hole in the center of the squared tip of the 2-Way Stop. Turn the wrench clockwise until the bottom rail begins to jog downward. This will set the uppermost point for your shade. Operate the shade a few times to ensure it is set properly.

Step 12: Disengage the 2-Way Stop from the bracket and place the tip onto the holding notch designed into the Pin End/2-Way Stop bracket. This will allow you to move to the left of the shade and slowly ease the clutch head pin outward to expose the Safety Pinhole. Once the hole is accessible, insert the Safety Tension Pin. It is now safe to remove the shade for packing without worrying about losing the tension.

Final Step: Complete all adjustments as desired.